“At Kovenco, we believe in a collaborative approach to business development and greater efficiency. In order to help our clients enhance the efficacy of their business operations through a cohesive team effort, we provide innovative lean six sigma consulting services in US & Canada, UK, Australia, Middle East and Dubai."

Lean six sigma is a lauded and widely-used approach that combines two innovative methodologies Lean Production and Six Sigma to eliminate defects in a business process and boost production. We take pride in deploying adept lean six sigma experts that provide clients with state-of-the-art consultancy solutions that develop a culture of continuous business development.

Six Sigma Methodology (DMAIC, DMADV, DFSS)

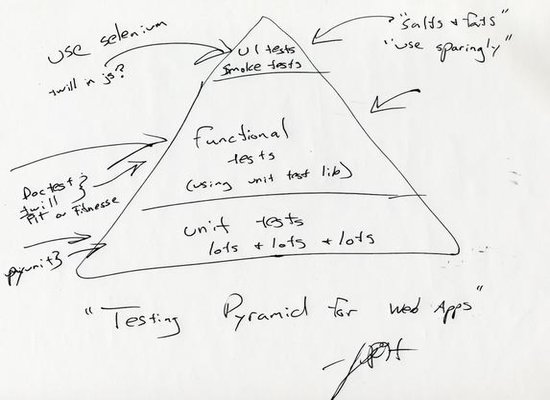

One size fits all is not our recipe for performance improvement and sustainable business growth. Each client, every business call for a unique strategy and thus we present you with a lean six sigma solution of your own – one that fits in your business well and meets your specifications. Six Sigma is a rigorous problem solving methodology that uses well-defined progression phases of Define, Measure, Analyze, Improve and Control, popularly known by the acronym, DMAIC. Define is problem definition, making sure you are solving the correct problem. Measure is gathering data that helps explain the problem. Analyze is reviewing the data to find patterns that lead to the root cause. Improve is making changes in the process based on the analysis. Control is achieved by putting process steps in place to ensure improvements are sustained. For the design and development of new systems or processes, there is a similarly defined progression of phases known as Define, Measure, Analyze, Design and Verify (DMADV) or also referred to as Design For Six Sigma (DFSS).

Continuous Improvement

There is often confusion between the similarity and difference of process improvement and continuous improvement, and where Lean Six Sigma consulting fits. Process improvement is the action of using Lean Six Sigma to make improvements to processes and solve difficult process problems. (Lean is often called Lean Process Improvement). Continuous improvement is the ongoing journey a company (or individual) will undertake to endlessly make “continuous or incremental” improvements to processes, people and functions in their organization. If you have heard of Kaizen Events, the word, Kaizen, literally means “change is good” but it’s spirit is to make continuous improvement in your organization. Lean Six Sigma is one of many methods to support continuous improvement.

Our aim at Kovenco is to improve the performance of your organisation and professionals in terms of operational speed and costs, quality and customer satisfaction. With our qualified lean six sigma consultants, we are able to not just achieve high performance but sustain that performance and competitive advantage in your organisation.

Proven Techniques

Kovenco has over 20 years of experience with Lean Six Sigma consultants. We have implemented hundreds of Lean Six Sigma projects and have led thousands of Lean and Six Sigma training workshops. Our staff are highly trained Master Black Belts (MBB) and our key differentiator is our focus on implementation with supporting education. We take our clients through the DMAIC process in a practical way that leads to knowledgeable teams and sustainable results. In addition, we have implemented Lean Six Sigma in many different industries including service, retail, distribution and manufacturing. When choosing a Lean Six Sigma consulting firm you should make sure there is a good personality fit and that the firm balances implementation and training in order to help make Lean Six Sigma and continuous improvement become a part of your company’s culture. We believe the best Lean Six Sigma consultants will want to educate people but also make sure that real improvements are achieved and sustainable. We leverage proven tools and techniques to incorporate lean six sigma discipline into organisations across a wide range of industries. All our practices and strategies are tested before implementation to ensure that they work in favour of your business and drive you sustainable benefits no matter your needs and the size of your business.

src="http://placehold.it/1920x500/f4f4f4/ddd" data-fullwidthcentering="on" alt="slidebg1" data-bgfit="cover" data-bgposition="center center" data-bgrepeat="no-repeat">

src="http://placehold.it/1920x500/f4f4f4/ddd" data-fullwidthcentering="on" alt="slidebg1" data-bgfit="cover" data-bgposition="center center" data-bgrepeat="no-repeat">